Imagine if you had a “bucket of stuff”1 that could do all your most tedious household chores for you. Washing the dishes. Vacuuming the floor. Cleaning the rain gutters. All you had to do was dump the bucket’s contents on the ground, send a command through your smartphone, and then sit back and relax as all your chores were done. This dream sounds too good to be true. But, as recognized by Yim et. al, in their 2007 article, “Modular Self-Reconfigurable Robot Systems,” the field of modular self-reconfigurable robots promises this and much more in the future.

Modularity

To understand what modular self-reconfigurable robots are, let’s begin by asking what it means for something to be modular. In the most general sense, the condition of being modular means being composed of relatively simple and standardized components – modules – that can be recombined to create other more complex systems. In other words, it means using simple modules to make something complex.

Modularity Around Us

You’ve seen modularity before. Popular media, especially Hollywood, have been fascinated with the possibilities (in many cases, dangers) of robots, self-reconfigurable ones in particular. In recent years, the Transformers franchise has been a blockbuster, centered on powerful robots capable of transforming into harmless looking cars and aircraft.

This idea of modularity isn’t just futuristic thinking or some human invention. Modularity exists all around us in nature. Biological systems are composed of cells (amino acids and other macromolecules at lower levels) that are quite modular. They grow, heal, die, adapt to new circumstances, and even are replaced when necessary. When one looks at a tissue system with respect to the overall system, the tissue’s cells are all relatively similar and simple.

Modularity isn’t limited to organic things either. Elements and their basic building blocks – atoms – make up everything we know in the physical world. For example, graphite – the material in your pencil lead – and diamonds are two very different substances but composed of the same carbon atoms – albeit organized differently in the most basic sense.

Modular Self-Reconfigurable Robots

But what exactly makes modular self-reconfigurable robots unique? Modular self-reconfigurable robots are composed of units that the robots themselves can rearrange to adapt to different environments and tasks. With a given set of modules, these robots can change their shape to form different robots, similar to the way Transformers morph their machinery.

These modules connect to each other through uniform interfaces, allowing the modules to form one cohesive structure. This is similar to the way Lego bricks perfectly attach to each other through their ubiquitous pins. Like human joints, these connectors allow “transfer of mechanical forces and moments [torques], electrical power, and communication throughout the robot.”1

Fig. 1 Robot Module Connectors

Fig. 1 Robot Module Connectors

Image reprinted with permission of MIT Press from Stoy K., Brandt D., Christensen D.J. Self-reconfigurable Robots: An Introduction. Cambridge, MA: MIT, 2010. p 4.

Figure 1 depicts an ATRON module with its two sets of protruding male connectors and two sets of female connector bars. The module can connect to neighboring modules by using its male connector hooks to grab onto a neighboring module’s corresponding female connector bars. The process is the same for disconnecting from other modules, except in the reverse order.2

In a sense, these interfaces are like Universal Serial Bus ports, commonly known as USB ports. Almost all devices that you plug into your computer – smartphones, tablets, mice, keyboards, flash drives – use this ubiquitous connector. Through this universal interface, electricity can flow, powering devices and sending data signals.

While uniform docking connectors allow modules to form a robot, the modules themselves are what give the robot its functionality. Going back to the Lego analogy, not all bricks are functionally identical. There are structural bricks, but also others that allow for movement such as wheels and axles. The same is true for self-reconfigurable robot modules. There are standard structure units, but also specialized drive, articulation, and control modules equipped with different equipment such as claws, cameras, drive systems, power sources, microcontrollers, and more. Some modules developed in research are even capable of deforming, which may be potentially useful in certain applications. For some robots, the control system – the part of the robot that tells the robot what to do – is spread over all of its modules, whereas others centralize the control system in a few modules. Depending on the task at hand, the robot will integrate the required modules into the system. With so many different possible modules and ways to connect them, the possibilities are endless.

Classification

Modular robot systems can be classified in multiple ways: how the modules are arranged, how the modules get rearranged, and how the modules are designed.

There are three ways modules are arranged: lattice architecture, chain architecture, and a hybrid of the two. In lattice architecture-type systems, modules are interconnected in an orderly, repeating three-dimensional grid. This is analogous to the way atoms are arranged in a crystal. Given the uniform layout of the system, this architecture allows for relatively simple mechanical design. For each reconfiguration step, modules disconnect, move to their target location, and reconnect. Because each module has a set number of locations it can move to, system reconfiguration is also relatively simple and can be done using an open-loop control system. An open-loop control system essentially takes inputs and generates outputs without any feedback. One example of this is a washing machine, which takes inputs (load size, clothing type) and outputs a wash cycle without any feedback. Perhaps most importantly, this uniform structure is relatively easy to scale to larger, complex systems.6

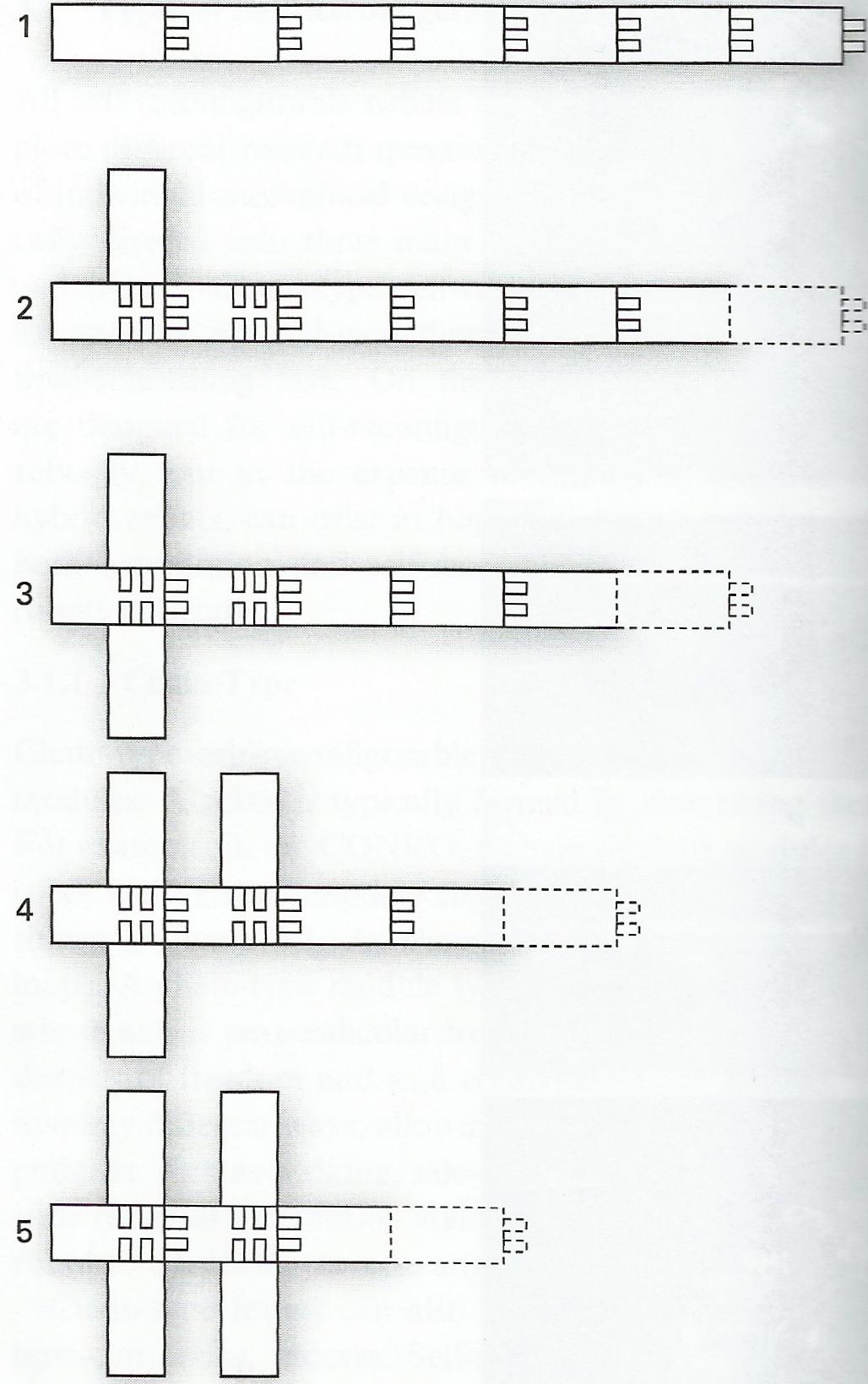

In chain or tree architecture-type systems, modules are connected like links in a chain, one after the other. There is no network or grid of predetermined interface points, thus allowing the system to reach any point in space. This vastly increased versatility makes chain-type robots well suited for locomotion. However, it also makes the system much harder to control, especially during reconfiguration steps. In addition to the steps required for reconfiguration in lattice-type systems, chain-type modules need to search for the module they are going to connect to because its location is not known. This complexity necessitates use of closed-loop control. A closed-loop control system essentially is the same as an open-loop control system except that the controllers are constantly adjusting their output based on feedback. One example of this is a thermostat, which takes in an input (desired temperature) and adjusts the output (heat) based on feedback (current temperature). This complexity is further increased when scaling to larger, more complex systems.6

Units may also form lattice architectures to make self-reconfiguration easier or form chains to make locomotion easier, taking advantage of each architecture’s strengths in appropriate circumstances. These systems are regarded as hybrid or mobile architectures. As Stoy et al. note, “hybrid modules are not necessarily more complex than lattice-type or chain-type modules, but rather obtain their hybrid nature by using geometry that fits in a lattice and by placing the degrees of freedom in a way that allows for flexible chains.” Because of the increased versatility with no additional complexity, most modern systems are hybrids.2

Modular robots can also be categorized by the way they rearrange their modules. The two main ways are deterministic reconfiguration and stochastic reconfiguration. With deterministic reconfiguration, the system either moves the units or the units move themselves. Under this method, “the exact location of each unit is known at all times or can be discovered and calculated at run time, and reconfiguration times can be guaranteed.”1 Because each module location needs to be known, precise feedback control is required, especially in chain-type and hybrid-type systems, and as a result, this method requires more computation power.1

Fig. 2 Diagram of Chain-type robot self-reconfiguring from snake configuration to four-legged walker configuration.

Fig. 2 Diagram of Chain-type robot self-reconfiguring from snake configuration to four-legged walker configuration.

Reprinted with permission of MIT Press from Stoy K., Brandt D., Christensen D.J. Self-reconfigurable Robots: An Introduction. Cambridge, MA: MIT, 2010. p 44.

In stochastic reconfiguration systems, units seem to move randomly as they use energy from the surrounding environment to rearrange themselves. Their behavior is that of particles undergoing Brownian motion, where the particles seem to move randomly after colliding with molecules in a fluid. As a result, the modules’ “location is only known when they are connected to the main structure… and reconfiguration times can be guaranteed only statistically.”1 Given the size of their modules, macro-scale systems are usually deterministic and micro-scale systems are stochastic, as they will undergo Brownian motion in almost any fluid environment.1,7

Systems can also be classified by their module design. Homogenous systems utilize many similar modules to accomplish a task. Because the modules are similar, the system is easy to scale in size and function as needed. For example, if a modular car originally configured for carrying children needs to carry football players, it can just increase its size and power by adding a number of units proportional to the increase in payload. These systems are also relatively inexpensive, as they use similar modules and can utilize economies of scale and mass production to lower the cost of each module. Most self-reconfigurable robots are composed of homogeneous modules.2 Heterogeneous systems utilize more sophisticated and powerful modules than their homogenous counterparts. Consequently, fewer modules will be needed to accomplish each task, allowing these systems to be more compact. Furthermore, because relatively few modules are needed to complete each task, the systems are more versatile. An example of this is a Swiss Army knife. Depending on the task at hand, you can select different specialized tools such as a blade, screwdriver, scissors, and more, rather than using one tool for all jobs. However, because of this increase in complexity, heterogeneous systems are more complex in all aspects – design, manufacturing, control simulations – and are accordingly more expensive than homogenous systems.2

Advantages and Disadvantages

Modular self-reconfigurable robots offer a few potential advantages over conventional robots. Given their self-reconfigurable nature, modular robots are more versatile than their conventional counterparts. Modular robots can reconfigure their modules to morph into the optimal form for the task at hand or their current environment. For example, a modular robot going through various terrains could change its shape for optimal performance. If it were going over a relatively smooth path, it could make itself into a wheel or ball to move quickly using minimal energy. However, once it encountered uneven rocky terrain, obstacles, or even steps, the robot could form legs to climb over barriers. It could even form a snake-like morphology to slither through small spaces, particularly useful in emergency situations. This is not possible with conventional robots since they can only assume one form.

“Modular robots are also more robust than their conventional counterparts. No individual module is critically important as each can be replaced relatively easily.”

Modular robots are also more robust than their conventional counterparts. No individual module is critically important as each can be replaced relatively easily. If one module fails due to a hardware or software issue, the entire system does not break down. Since they are reconfigurable, modular systems can compensate for damage by reconfiguring, or even by replacing the part autonomously if they have access to additional units from nearby robots or their environment. Moreover, if a tool is not working for a task, modular robots can reconfigure to better adapt to the task at hand or even get a new module better suited for the task. This self-repair and adaptation allows for modular robots to deal with damage and complications far better than conventional ones. As Stoy et al. write, “its [modular robotics system] performance degrades gracefully with the number of failed modules.” 2

Modular robots can potentially be cheaper than conventional robots. With a relatively small number of modules accomplishing many different tasks, the cost of each module can be driven down through economies of scale and mass production. This is especially the case with homogenous systems. Even heterogeneous systems may cost less than conventional systems because only one robot with different modules is needed rather than multiple robots.

If modular robots are so great, why don’t we have them today? The very things that make modular self-reconfigurable robots unique and potentially powerful – modularity and self- reconfigurability – make them especially difficult to produce. With all the added degrees of freedom – dimensions in which motion can be achieved such as forward and backwards translation or rotation – mechanical and control complexity skyrockets. Although much progress has been made, the field remains in its research phase because of this complexity. One inherent disadvantage of modular robots is that they will be inferior to specialized robots at each task. This is perhaps best described by the popular figure of speech, “jack of all trades, master of none.” Yim et al. put it most accurately in their overview of the field: “Consequently, the advantage of modular robotics is only apparent when considering multiple tasks that would normally require a set of different fixed-morphology robots, or when the nature of tasks cannot be fully determined before the robots are deployed.” 1

Application

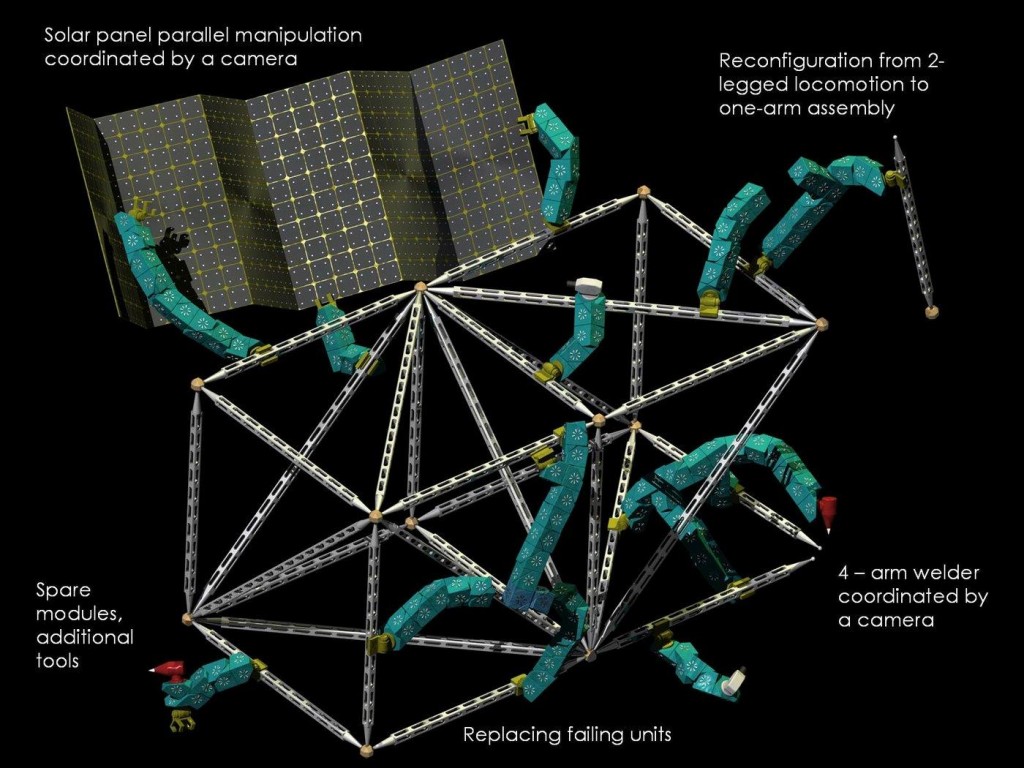

Two possible applications for self-reconfigurable modular robots are long-term space missions and the bucket of stuff scenario described earlier in this paper. Modular robots are ideal for long-term space missions because many unexpected circumstances will occur on an extended journey. Systems need to be able to adapt to unforeseen situations and repair themselves because once the mission begins, there will be no access to additional supplies. On space missions, every square inch and pound is precious. Modular self-reconfigurable robots are perfect for this scenario as they theoretically could accomplish many tasks with a relatively small number of modules, as shown in Figure 3, creating a smaller footprint than conventional systems.3

Fig. 3 Space Molecubes: Space Application of Modular Self-Reconfigurable Robots

Image credit: Victor Zykov Creative Commons License

As described in the beginning of this article, modular robotics systems also offer the possibilities of completing multiple undesirable household tasks while remaining in a relatively small package, such as a bucket of stuff. This capability has, at the very least, some commercial value.

Current State

According to Yim et al. writing in 2007, much has been accomplished in the field of modular robotics– specifically with respect to system size (at both ends of the spectrum) and performance.1 However, the real potential of self-reconfigurable modular robots lies in the number of modules in the system. Physical systems have been made with as many as 56 active modules in a connected system, but this number has not increased for over a decade due to various limiting factors. Although software algorithms have been developed to handle millions of modules operating simultaneously in ideal conditions, many challenges in hardware and algorithm design have to be overcome before physical systems of that scale can become a reality. On the hardware side, researchers have worked on optimizing individual aspects of mechanical and electrical design, such as the size of modules, module strength, and module battery life, but have not developed a standard module design encompassing all their findings.1 This failure is due to multiple factors: the limited strength, precision, and robustness of module interfaces, the physical limits of current motors, and the limited functionality of modules. On the computational side, there are many issues to resolve concerning scalability in real-world algorithm design for millions of modules, both at the low level and high level (“low level” deals with the individual components of a system whereas “high level” refers to the overall system). Developing generic algorithms that work with completely different systems will be even more difficult. Most of these challenges involve large-scale operations with and without obstacles. Challenges include conducting simultaneous reconfiguration and locomotion, determining optimal reconfigurations efficiently with respect to energy and time, handling failures robustly (dead units, misalignments, defective units), and communicating between many modules efficiently.1 Two major combined software and hardware challenges are decision-making using sensor data from a large network of modules and dealing with obstacles and uncontrolled environments such as natural disaster sites. These scenarios will render any previously stored data completely useless, forcing the system to adapt using new data from its network of modules equipped with sensors.

The Next Phase

Looking at the future direction of the field, prominent researchers in this field including Mark Yim and Daniela Rus have outlined “‘grand challenges’ that, if overcome, would realize a next generation of modular robots with vastly superior capabilities.” 1 Those “grand challenges” are summarized in the following paragraph. The first challenge is developing systems with at least 1,000 modules to approach the complexity of biological living cells. Such a large system would entail many new mechanical challenges including power distribution as well as requiring new control algorithms to handle systems of this scale.5 The second challenge is developing truly self-repairing systems capable of reassembling after being thoroughly disassembled and recovering from the failure of numerous modules. This goal requires extensive rethinking of mechanical, electrical, and algorithm designs to significantly increase robustness. The third challenge is developing long-term self-sustaining systems. This requires determining new ways of managing and harvesting power as well as dealing with system failures, all without human interaction. The fourth challenge is achieving self-replication from raw materials. This level of self-sustainability would open worlds of possibility but “would require advancing beyond a level of complexity that Von Neumann [a brilliant Hungarian mathematician and polymath] identified as essentially the equivalent of the sound barrier for engineered systems.” 1 The fifth challenge is termed “reconciliation with thermodynamics.”1 It involves using stochastic fluctuations – random movements of molecules in a fluid– at the micro or even nano-scale to self-organize modules in a solution. This would allow major energy savings to overcome entropy.7 These challenges are further expanded upon in Yim et al.’s article “Modular Self-Reconfigurable Robot Systems”1.

Possibilities

Over the past twenty years, the field of self-reconfigurable robots has progressed a long way. Although there are many challenges, as increasing numbers of researchers enter this field, more exciting work will be done and the field of robotics will be revolutionized. The possibilities of modular self-reconfiguring robots are endless.

References

Yim M., Shen W.M., Salemi B., Rus D., Moll M., Lipson H., Klavins E., Chirikjian, G.S. “Modular Self-Reconfigurable Robot Systems” Robotics Automation Magazine, IEEE 14, no. 1 2007: 43-52.

Stoy K., Brandt D., Christensen D.J. Self-reconfigurable Robots: An Introduction. Cambridge, MA: MIT, 2010. 195 p.Zykov, V., Mytilinaios, E., Desnoyer, M., Lipson, H. “Evolved and designed self-reproducing modular robotics.” Robotics, IEEE Transactions on 23.2 2007: 308-319.

Butler, Z., Kotay, K., Rus, D., & Tomita K. “Generic decentralized control for a class of self-reconfigurable robots” Robotics and Automation, 2002. Proceedings. ICRA’02. IEEE International Conference on (Vol. 1). 2002: 809-816.

Tolley, M.T., Lipson H.. “Fluidic manipulation for scalable stochastic 3D assembly of modular robots.” Robotics and Automation (ICRA), 2010 IEEE International Conference on, 2010: 2473-2478.

Østergaard E.H., Kassow K., Beck, R., Lund H.H.. “Design of the ATRON lattice-based self-reconfigurable robot.” Autonomous Robots 21, no. 2. 2006: 165-183.

White P., Zykov V., Bongard J., Lipson H. “Three dimensional stochastic reconfiguration of modular robots.” Proceedings of robotics science and systems. 2005: 161-168.